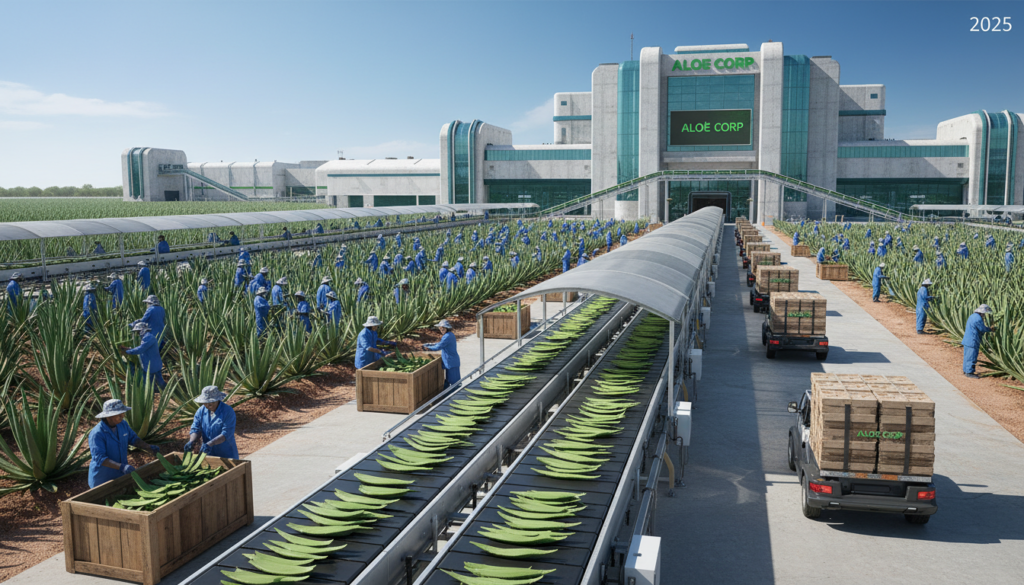

Aloe vera gel production involves several steps, from harvesting to packaging. Here’s an overview of the industrial process:

- Harvesting: Fresh aloe vera leaves are cut from the plant, typically within 36 hours to preserve biological activity.

- Cleaning and Preparation: Leaves are washed and trimmed to remove thorns and damaged areas.

- Gel Extraction: The gel is extracted using machines or hand-filleting, separating it from the leaf’s outer rind.

- Milling and Filtration: The gel is milled into a pulp and filtered to remove impurities.

- Stabilization and Blending: Preservatives and stabilizers are added to maintain the gel’s texture and shelf life.

- Pasteurization: The gel is heated to ensure safety and extend shelf life.

- Filling and Packaging: The gel is filled into containers, sealed, and labeled for distribution

The production process may vary depending on the desired product, such as cosmetic, pharmaceutical, or food-grade gel. Quality control measures are implemented throughout the process to ensure consistency and purity